LINGYI AIR SLIDE CANVAS

Air Slide Pneumatic Conveyor Systems consist of Air feed unit like blower, metallic bellow or compressor which are the sources of air stream supply; product feed pneumatic conveyor comprising two pressurized chambers or channels, positioned one upon another at their open trough ends with the Air Slide Fabric separating them. The pressurized air is fed into the bottom chamber and permeates through the fabric entering the top chamber where it picks up the product being feed into it at the upper gradient end transports it to the collection point at the lower gradient end.

There is an air separation arrangement at collection point or filter unit, which separates the solid powder product stream from the air stream. This may be a cyclone separator, bag house filter or precipitator and material product is collected in bin, silo, or hopper either for storage or mixing or blending or if in a finished product stage to the packing plant.

Description

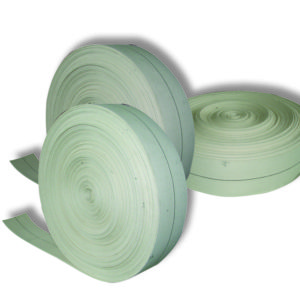

· Air Slide Fabrics produced from 100% Polyester (spun/filament), 100% cotton, 100% Nomex® in widths of 200mm up to 2000mm and thickness in 3.0, 4.0/4.5, 4.8 /5.0, 6.0/6.5/8.0/10/12mm.

· Available in roll lengths and cut pieces to actual installation size & shape.

· Materials inspected & tested with Test & Guarantee Certificates provided.

· Air Slide Fabrics for all Pneumatic gravity Conveyor System i.e. Air Slide, Fluidor, Fluxo-Channel Fluid Slide, Aeration – Box, Airlift or Aerpole pumps in Sillo, Bin & Hopper.

· For bulk material conveying fine crushed and ground powdered chemical mineral substances used to manufacture cement as well as any other similar powdered products.

· Our “Air Slide Fabrics” have good abrasion resistance offered in 100% Synthetic qualities of polyester to withstand organic and inorganic chemicals, acids, alkalis and oxidizing agents contained in raw mix, clinker and cement.

LINGYI PURIFICATION provide Air slide belt for conveying bulk material by air gravity. The main use of Air slide belt is discharging, declining transportation or homogenizing the powder or small granular material in quiescent condition. Our airslide belt is named as Air slide fabric, Air slide membrane, Air slide cloth, Air slide canvas, Air permeable fabric, and Fluidization cloth, fluidising fabric, etc by our customer. We adopt 100% polyester for air slide fabric material.

Our fabrics can be used at temperatures between -60°C and +150°C. The air slide fabrics are made from polyester yarns. We are also, however, able to weave fabrics to our customers’ specific demands for air permeability and mechanical strength.

In cement plant:

An Air slide belt is in the middle of a chute. Powder material will come into the chute above Airslide belt. Material will flow to the chute lower side as pneumatic blower down Air slide belt. That’s why we say Airslide belt can move powder material because of the wind power. And then, the rest wind will go out from the top of the chute. Through the moving, no parts moved except powder material. So that it can spare more energy and maintain cost, etc.

Our Air slide canvas is installed on the surface of the silo bottom. It is supplied for installation as aeration units on the sloped conical bottoms of bins and silos to aid in the withdrawal of dry relatively free-flowing material.

Each Air slide aeration unit package consists of 200mm open-type. Airslide conveyor units in lengths of 1.5 or 3m depend on the slope length of the conical storage area. Some spoke patterns are normally used with materials which have good fluidization characteristics. Others spoke patterns provide maximum aeration for difficult materials which can be fluidized.